Druck MCX II Documenting Process Calibrator

A CALIBRATION WORKSHOP IN A SINGLE INSTRUMENT

The Druck MCX II portable documenting calibrator is the most

comprehensive field calibration tool available. It is the culmination of

many years combined field experience with the Druck and Unomat series

of portable pressure, temperature and electrical calibrators. Designed for

field use, this rugged, self-contained, battery powered package simulates and

reads RTD’s, thermocouples and resistance, as well as sourcing and reading

milliamps, millivolts, volts and frequency. With interchangeable single and dual

sensor pressure modules over 90 input and output ranges are available.

The MCX II saves time and money with the calibration, maintenance and

commissioning of instrumentation for process plants, production lines, utility

processing and distribution by:

• Reducing the burden imposed by quality systems such as ISO 9000.

• Reducing calibration, maintenance and commissioning time.

• Reducing documentation time and errors

• Replacing several standard test instruments.

• Reducing test instrument calibration costs.

• Minimizing down time and maximising efficient field usage.

• Input/output mA

• Input/simulate 12 types of T/C

• Input/simulate 9 types of RTD

• Input/output frequency and pulse

• Simulate transmitter input and measure transmitter output

• Input/output mV/V

• Input/output resistance

• Measure pressure: -14.7 to 5000 psi

• Test switches: captures values on contact change

• Trim smart HART transmitters

For example, a typical thermocouple transmitter calibration can take one

hour using a mV source, look-up tables and a milliammeter. In just five minutes

the MCX II can make an automatic calibration and document the results while

virtually eliminating human errors. A PCMCIA memory card provides data

storage and gives total flexibility to suit different working practices. By simply

exchanging PCMCIA cards, the MCX II can remain permanently in the field and

when compared to serial data transfer methods this can save one to two hours

a day. With a single item to calibrate the cost of re-calibration is reduced and the

inconvenience of down time is minimized.

HART® communicator for SMART transmitters

The HART® communicator allows digital field adjustment of smart transmitters.

Typical adjustments to sensor and analogue trims can take up to 40

minutes using conventional test equipment and a hand held communicator.

With a single MCX II this time can be reduced to less than 10 minutes,

including a fully documented calibration.

High precision and multi-functional

Typical accuracy: 0.01% Rdg +/-0.003% FS for mA measurement

0.05% Rdg for pressure measurement,

Input: mA, mV, volts, T/C’s, RTD’s, pressure, ohms, frequency and switch state.

Output: mA, mV, volts, T/C’s, RTD’s, ohms, and frequency.

Pressure modules: Interchangeable single and dual ranges from -14.7 to

5000 psi including gauge, absolute and differential.

HART® communicator: HART® digital communicator for SMART transmitters.

C/J compensation: Internal, external and manual.

Loop Power: Dual 24 Vdc.

Temperature probe: 1/5 DIN accuracy P100 probe.

Data storage: 1 Mbyte PCMCIA card.

Data transfer: PCMCIA card or RS 232 interface.

PC software: Linkpak-W and Intecal-W.

Easy to use

The multi-lingual user interface is an easy to use Input/Output

menu with dual parameter readout. The Input and Output connectors are

standard 4mm gold plated sockets which are separated and clearly labelled.

The rugged impact resistant enclosure is surrounded by a durable protective

carry case which allows access to all the instrument features and provides

convenient pockets for storing test leads and accessories. Whether the

MCX II is horizontal orvertical the rotatable display provides the optimal

viewing angle. On the bench, test leads and pressure modules connect to

the front face. In the field, with the MCX II held vertically by the wide neck strap,

the connections are made to the rear face. With safety a major design concern,

these features reduce the possibility of dropping equipment as the operators hands

are kept free.

The MCX II has been designed for ease of use while meeting a wide

range of application needs including calibration, maintenance and

commissioning. The dual parameter display shows the input and output

values in large clear digits with all applicable information such as the

units of measurement and range. Using the rotating display, the rear

face electrical connectors and wide neck strap, the instrument can be

safely worn around the neck or fastened to a suitable pipe or valve.

This leaves the operators hands free at all times and prevents

dangerous dropages. The easy to operate menu driven software

enables the MCX II to be set-up very quickly. Simply scroll

through the input and output menus to select the required parameters.

Operating and connection errors such as loop resistance mismatch and

cold junction temperature sensor absence are reported. The

KEYSTROKING memory enables instant recall of previously stored

user tests.

Technical Specifications:

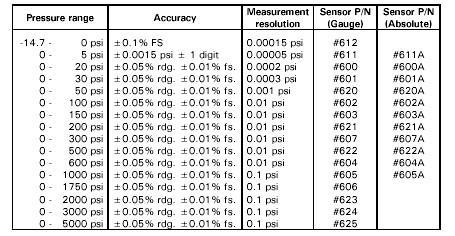

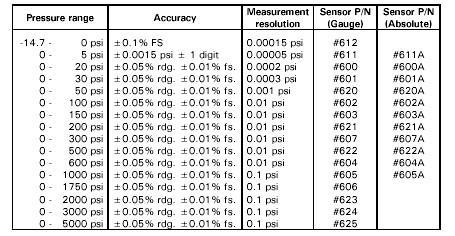

Pressure Range Selection Table:

|